When you’re in the food manufacturing industry, every component of your production line should meet the highest standards of hygiene and efficiency. That’s where Clean Geartech food safe aluminium & stainless-steel motors & gearboxes shine. Designed specifically for environments where cleanliness is key, these motor & gearbox solutions offer manufacturers peace of mind, alongside a host of operational benefits.

Equipped with features such as corrosion resistance, smooth surfaces to prevent bacterial growth, and the ability to withstand high-pressure washdown, Clean Geartech motors & gearboxes are engineered to ensure your production line remains uncontaminated and compliant with stringent hygiene standards. This not only helps safeguard consumer health but also enhances your manufacturing process’s reliability and longevity.

Choosing the right motor & gearbox solution for your manufacturing needs can dramatically reduce maintenance costs. Thanks to the durable construction of Clean Geartech products, the risk of food safety incidents is minimised, ensuring your operations run smoothly and efficiently.

Let’s delve deeper into what makes Clean Geartech hygienic motors and gearboxes a smart investment for your manufacturing line.

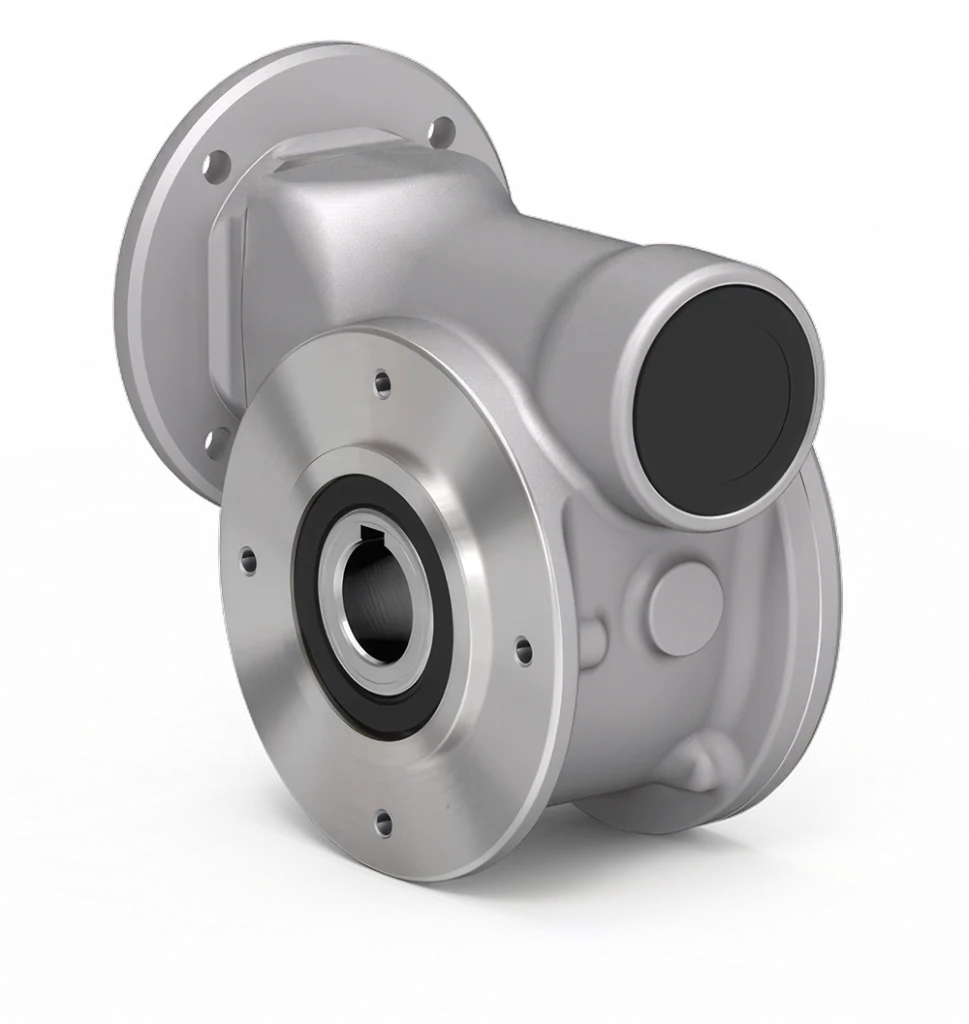

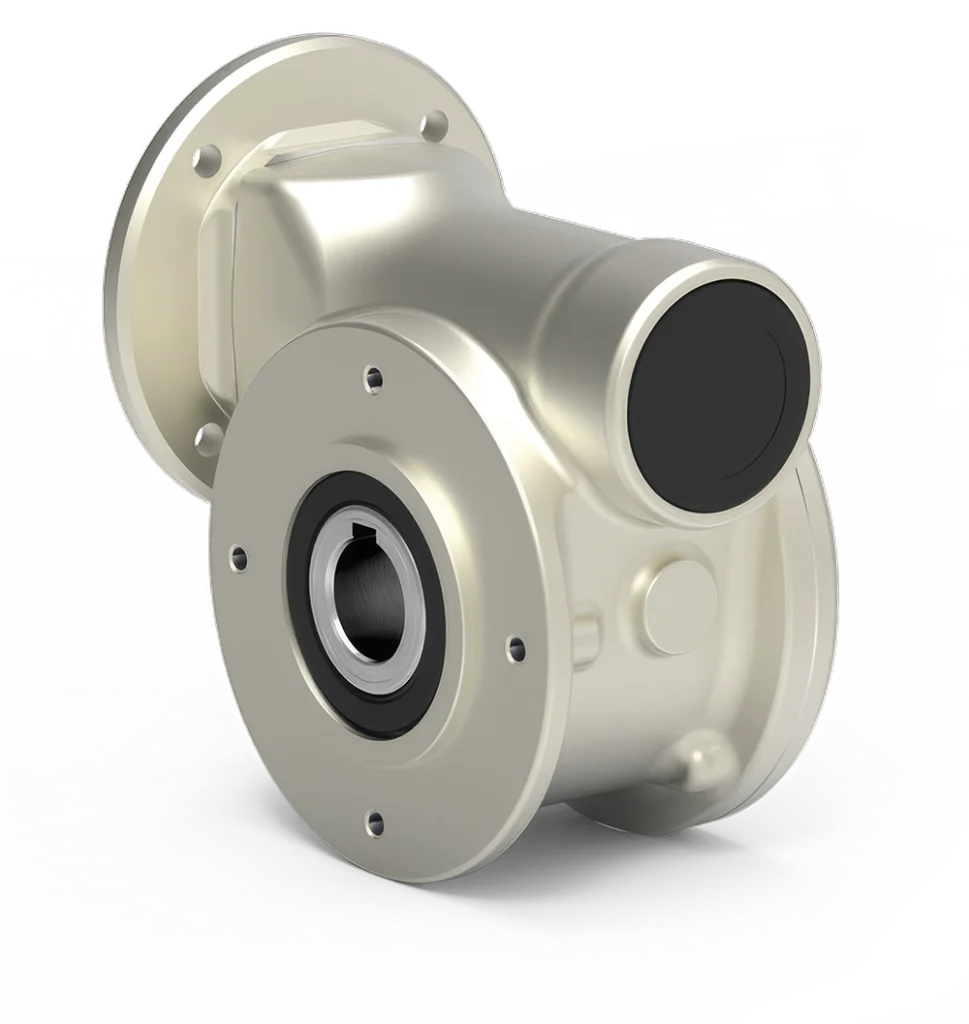

Clean Geartech hygienic motors & gearboxes are engineered to meet the rigorous demands of the food manufacturing industry. These motors feature a stainless steel or aluminium construction that resists corrosion, an essential quality for environments exposed to water, chemicals, and extreme temperatures. This makes them perfectly suited for applications that require frequent cleaning and sanitation, ensuring no compromise on hygiene.

Their design prioritises not only durability but also the prevention of contamination. With smooth surfaces that inhibit bacterial growth and the capability to endure washdowns with high-pressure water, Clean Geartech offer an unparalleled solution to maintaining a sterile production environment.

This level of protection is vital for any food processing operation aiming to uphold the highest standards of food safety.

In the realm of food manufacturing, the stakes for cleanliness and safety cannot be overstated. Contamination can lead to severe health risks for consumers and devastating reputation damage for producers.

Food-safe hygienic motors and worm gearboxes, like those from Clean Geartech, are designed to address these risks head-on, offering manufacturers a way to uphold safety without compromising on efficiency.

The use of food-safe equipment goes beyond just meeting possible legal requirements. It’s about ensuring the longevity of your manufacturing equipment and the sustainability of your production processes.

By choosing gearboxes and motors that are built to withstand the harsh conditions of food processing environments, you’re making a long-term investment in your company’s future, prioritising both consumer safety and operational efficiency.

Navigating the landscape of hygiene standards can be daunting for any food manufacturer and keeping abreast of local food safety regulations is an important part of the job.

These rules outline the necessary conditions for machinery and equipment used in food processing, ensuring that everything from cleanliness to contamination prevention is addressed.

Compliance is not just about avoiding legal repercussions; it’s about demonstrating your commitment to producing safe, high-quality food products.

The UK has a rigorous food safety framework that stands out for its emphasis on transparency, risk assessment, and consumer protection.

The regulations are primarily governed by the Food Standards Agency (FSA), which enforces strict rules on food hygiene, safety, and labeling. The UK adheres to the Food Safety Act 1990 and General Food Law Regulation (EU) 178/2002, ensuring comprehensive control over food safety and hygiene from production to retail.

These standards are designed to protect consumers by ensuring that food products are made in a clean, safe environment.

For manufacturers, this means that every piece of equipment, including motors and gearboxes used in the manufacture of food products, must meet specific requirements for hygiene and contamination prevention.

The regulations emphasise the importance of using materials that are easy to clean and maintain, and that can withstand the rigors of food processing environments. This includes resistance to corrosion, the ability to handle frequent washdowns, and designs that prevent the harbouring of bacteria.

Clean Geartech hygienic solutions bring to the table a suite of features designed to meet the unique needs of the food manufacturing industry. With an emphasis on hygiene, efficiency, and durability, these are the go-to choice for manufacturers who refuse to compromise on quality and safety.

Let’s explore the key features that set Clean Geartech apart.

Corrosion resistance is a cornerstone of Clean Geartech hygienic motors and worm gearboxes. The use of stainless steel or aluminium in the frame, end shields, and hardware ensures that they can withstand the harsh conditions often found in food processing environments.

This resistance to corrosion is key for maintaining the integrity of the motor and ensuring that it remains a reliable component of your manufacturing line over time.

This durability against corrosive elements means that Clean Geartech motors and gearbox solutions are well-suited for applications requiring frequent cleaning with water, chemicals, and exposure to extreme temperatures.

By choosing equipment that is designed to last, you’re not only ensuring continuous operation but also reducing the need for costly replacements and maintenance.

The smooth surface design plays a pivotal role in preventing bacterial growth, a critical consideration in any food processing application. This design feature ensures that there are no crevices or rough surfaces where food particles and bacteria can accumulate, making it easier to maintain a high level of cleanliness and hygiene.

By facilitating more effective cleaning and sanitation processes, these help manufacturers meet stringent food safety standards, ensuring that the risk of contamination is minimised. This focus on hygiene extends beyond compliance, contributing to the overall quality and safety of the food products being manufactured.

With Clean Geartech gearboxes and motors, you’re investing in a solution that prioritises the well-being of your consumers and the reputation of your brand.

When you’re working in the food industry, keeping your equipment clean is not just important, it’s potentially the most important consideration. That’s why Clean Geartech hygienic solutions are designed to be water resistant and capable of withstanding high-pressure washdown. This means you can clean them with jets of water or even chemicals, and they won’t rust or corrode.

This is a game-changer for maintaining hygiene standards in your operations.

The materials used in these motors and gears, like stainless steel for the frame, end shields, and hardware, ensure they can withstand extreme conditions without deteriorating.

This sturdiness is especially important in environments with regular exposure to water, chemicals, and high temperatures. It gives you the certainty that your motors will keep running reliably when it matters most.

Introducing Clean Geartech hygienic motors and gearbox solutions into your manufacturing process brings a host of benefits.

1. Enhancing Hygiene and Reducing Contamination Risks

Hygiene is a top priority in food manufacturing, and Clean Geartech play a crucial role in minimising contamination risks. Their waterproof and washdown capabilities allow for thorough cleaning, ensuring that no harmful bacteria or contaminants compromise your food products.

2. Increasing Operational Efficiency and Reliability

The efficiency of your manufacturing process is directly tied to the reliability of your equipment. Clean Geartech hygienic motors and gearboxes are engineered to provide uninterrupted service, ensuring your production line runs smoothly.

3. Reducing Maintenance Costs Through Durability

Maintenance can be a significant expense in manufacturing, but Clean Geartech equipment is built to last. Their corrosion-resistant materials and waterproof design mean they require less frequent repairs, helping to lower your overall maintenance costs. This durability ensures your motors keep running for longer, providing a better return on investment.

Betech 100pt Ltd

Four Square Buildings, Thomas Street, Heckmondwike,

West Yorkshire WF16 0LS

Registered in England No. 240 4937

VAT No. 461 3067 67

Betech Terms & Conditions

To view our updated terms and conditions of sale