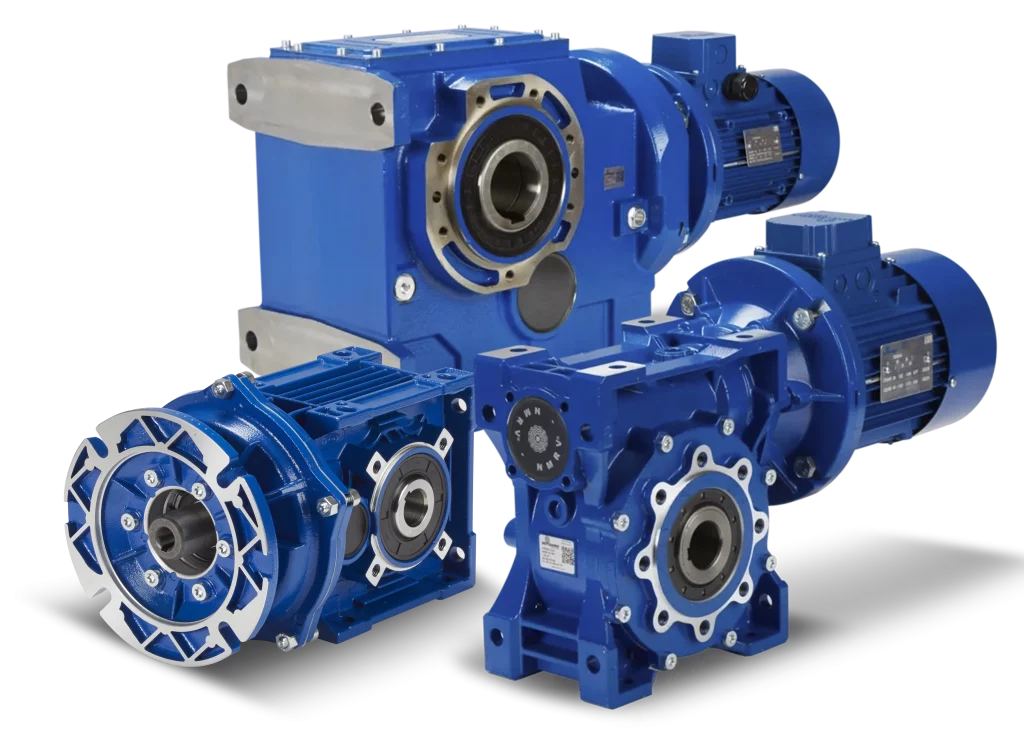

Gearboxes are crucial components in various industries, as they transmit mechanical power and torque from one rotating part to another. They come in different types, such as bevel, helical, and worm gearboxes. In this article, we'll discuss how each of these gearboxes works, their efficiency, advantages, disadvantages, and applications in different industries.

Bevel gearboxes are suitable for transmitting power between intersecting shafts, while helical gearboxes can transmit power between parallel or non-parallel shafts. Bevel gears are generally more compact while helical gears offer smoother, quieter operation.

Bevel gearboxes are generally more efficient and capable of handling higher speeds than worm gearboxes. However, worm gearboxes offer higher torque transmission and a self-locking mechanism, making them suitable for applications requiring high torque and compact design.

Helical gearboxes offer higher efficiency, smoother operation, and the ability to handle higher speeds compared to worm gearboxes. Worm gearboxes, on the other hand, provide high torque transmission, a compact design. The choice between helical and worm gearboxes will depend on the specific needs of the application, such as torque, efficiency, and space constraints.